In the competitive world of aerospace manufacturing, precision, reliability, and compliance are non-negotiable. As a leading sheet metal fabrication service provider in Mexico, we combine decades of industry expertise, cutting-edge technology, and rigorous quality controls to deliver mission-critical components for aircraft, satellites, and space vehicles. This article delves into every aspect of aerospace sheet metal fabrication—explaining processes, materials, standards, and our unique capabilities—to help potential customers understand why partnering with us ensures optimal performance, cost efficiency, and on-time delivery.

What is sheet metal fabrication, and why is it critical in the aerospace industry?

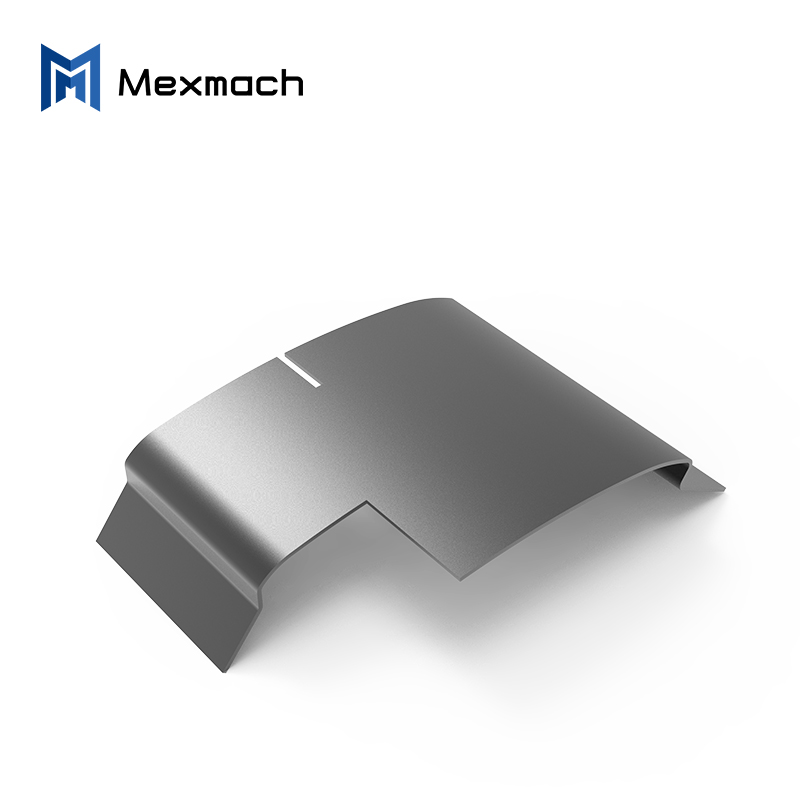

Sheet metal fabrication encompasses the cutting, bending, and assembling of thin metal sheets into precise components. In aerospace, where weight reduction, structural integrity, and aerodynamic performance are paramount, sheet metal parts form the backbone of fuselages, wing skins, control surfaces, brackets, and housings. High strength-to-weight ratios and tight tolerances make sheet metal indispensable for meeting both design requirements and safety regulations. Any deviation in form or finish can compromise aircraft performance or, worse, passenger safety—making it imperative to work with a fabricator that specializes in aerospace-grade components.

What types of sheet metal services do aerospace manufacturers require?

Aerospace OEMs and Tier-1 suppliers typically demand a wide array of value-added services, including:

-

Laser and plasma cutting for intricate shapes and minimal heat-affected zones

-

Precision CNC punching to create multi-hit patterns, lightening holes, and louvers

-

Press brake forming with multi-axis capabilities to achieve complex bends with tight radii

-

Roll forming for creating curved skins and fairings

-

Waterjet cutting for cutting exotic alloys without thermal distortion

-

Welding and fastening (TIG, MIG, resistance) to assemble sub-assemblies

-

Secondary machining (drilling, tapping, milling) to integrate features and ensure hole positional accuracy

-

Kitting and assembly to deliver ready-to-install components, reducing supply-chain complexity for aerospace integrators

Which materials are commonly used in aerospace sheet metal fabrication?

Aerospace applications demand materials that balance light weight, high strength, corrosion resistance, and fatigue life. The most prevalent alloys include:

-

Aluminum Alloys (2xxx, 5xxx, 6xxx, 7xxx series): Widely used for skins, ribs, and floor panels due to excellent strength-to-weight ratio and formability.

-

Titanium Alloys (Ti-6Al-4V): Employed in high-temperature zones (engine components, heat shields) for outstanding corrosion resistance and high-temperature performance, albeit at higher cost and machining difficulty.

-

Stainless Steels (300 & 400 series): Utilized for brackets, fasteners, and structural subcomponents where corrosion resistance and toughness are essential.

-

Nickel Alloys (Inconel, Hastelloy): Reserved for extreme environments near engines and exhaust systems, where temperatures exceed aluminum’s limits.

-

High-Strength Steels (HSLA, A286): Selected for landing-gear brackets and hard-wear components where fatigue and impact resistance are critical.

What precision and tolerances are required for aerospace parts?

The aerospace industry enforces some of the strictest tolerances in manufacturing:

-

Dimensional tolerances often range from ±0.005 in (±0.127 mm) for basic formed parts down to ±0.0005 in (±0.013 mm) for critical features such as bearing bores.

-

Flatness and straightness tolerances can be as tight as 0.001 in per foot (0.085 mm/m) to ensure aerodynamic surfaces meet design lift and drag specifications.

-

Bend angle accuracy of ±0.25° or better is required to guarantee proper assembly and load distribution.

-

Surface finish standards (Ra 32–125 μin) depend on location: exterior skins demand smooth finishes (Ra ≤ 63 μin) to minimize aerodynamic drag, while interior brackets may accept coarser finishes.

What manufacturing processes are involved in aerospace sheet metal fabrication?

Achieving aerospace-grade parts involves multiple, tightly controlled steps:

-

CAD/CAM programming: Creating digital models and nesting layouts to maximize material utilization while ensuring proper grain orientation and minimal waste.

-

Blanking and cutting: Laser or waterjet systems cut raw sheets with micron-level precision; nesting algorithms optimize part placement.

-

Forming: Press brakes equipped with CNC back-gauges and multi-axis crowning form complex bends, maintaining consistency across batches.

-

Secondary operations: Machining centers drill, tap, countersink, and mill additional features, ensuring hole patterns meet ASME Y14.5 GD&T specifications.

-

Assembly: Welding fixtures and rivet machines (C-frame, orbital riveting) build subassemblies; fixtures are designed to resist distortion and maintain alignment.

-

Finishing: Shot peening introduces beneficial compressive stresses to improve fatigue life; anodizing, alodine conversion coating, or powder coating enhance corrosion resistance and surface durability.

-

Inspection: Coordinate Measuring Machine (CMM) inspections verify critical dimensions, while non-destructive testing (NDT) methods—eddy current, dye penetrant, ultrasonic—detect subsurface defects.

How do advanced technologies enhance aerospace sheet metal fabrication?

To meet ever-tighter schedules and evolving aircraft designs, leading fabricators leverage:

-

Automated fiber-laser cutting for higher throughput and reduced kerf width

-

Robotic press brake cells that auto-load/unload and store tool sets for rapid changeovers

-

5-axis laser cutting heads enabling contour cutting and bevels in a single operation

-

Digital twin simulation to validate forming sequences, predict springback, and eliminate trial-and-error tool iterations

-

IoT-enabled machinery and Industry 4.0 dashboards for real-time monitoring of machine health, cycle times, and traceability of each part

-

Additive hybrid manufacturing for building stiffeners or reinforcing features directly onto sheet substrates, reducing weld joints and weight

What quality standards and certifications are essential in aerospace manufacturing?

Compliance with globally recognized standards underpins every aerospace contract:

-

AS9100 Rev D (Quality Management System for Aviation, Space, and Defense) ensures robust process controls, document traceability, and continuous improvement.

-

ISO 9001 forms the baseline QMS certification, often required alongside AS9100 for dual-market suppliers.

-

Nadcap accreditation for special processes such as heat treating, chemical processing (anodizing, conversion coating), and non-destructive testing—attesting to rigorous process audits.

-

MIL-STD-45662 and AMS 2750 compliance for heat-treat services, guaranteeing precise temperature profiles.

-

ITAR registration (International Traffic in Arms Regulations) for handling defense-related components, ensuring data security and export compliance.

How does surface finishing and coating impact aerospace components?

Beyond corrosion protection, surface treatments can enhance part performance and lifespan:

-

Anodizing (Type II & III): Increases wear resistance and electrical insulation for aluminum parts; Type III (hardcoat) yields thicker oxide layers for harsh environments.

-

Alodine conversion coating: Provides excellent adhesion for subsequent paint layers and enhances corrosion resistance on aluminum alloys.

-

Powder and liquid painting: Applied in controlled booths to meet FAA color and texture standards for interior panels and exterior fairings.

-

Phosphate coating: Prepares ferrous parts for painting and provides temporary corrosion protection during assembly.

-

Selective coatings: Thermal barrier coatings, dry lubricant coatings (e.g., MoS₂), and EMI shielding layers can be applied according to functional requirements.

What testing and inspection procedures ensure aerospace part integrity?

To guarantee zero defects, our quality department implements:

-

First Article Inspection (FAI): Verifying initial production parts against design specifications using CMM, optical comparators, and manual gauges.

-

In-process inspection: Operators perform check fixtures, laser scanners, and precision gauges at defined process steps to catch deviations early.

-

Final inspection: Comprehensive CMM reports, digital scan‐to‐CAD comparisons, and manual audits ensure dimensional conformity and surface quality.

-

Non-destructive testing (NDT):

-

Dye penetrant for crack detection on non-porous metals

-

Ultrasonic for thickness and delamination assessments in multilayer assemblies

-

Eddy current for surface and near‐surface defect detection in conductive materials

-

-

Documentation and traceability: Each part is labeled with a unique serial or batch number; material lot certificates, process logs, and inspection records accompany every shipment.

How can customization and prototyping benefit aerospace projects?

Early-stage prototyping accelerates design validation and reduces time to market. We offer:

-

Rapid prototyping through small-batch runs, enabling engineers to test fit, assembly sequences, and aerodynamics before committing to full-scale production.

-

Design for Manufacturability (DFM) consultation: Our engineers review CAD models to optimize bend allowances, hole placements, and material usage—cutting lead times and costs.

-

Flexible batch sizes: From one-off custom parts for R&D to production runs of thousands of units, we adjust capacity to meet program requirements without sacrificing quality.

-

Reverse engineering: 3D scanning and CAD reconstruction services allow legacy part reproduction when original drawings are unavailable.

Why should aerospace companies partner with a Mexican sheet metal fabricator?

Choosing a Mexican fabricator offers strategic advantages:

-

Cost competitiveness: Lower labor and overhead costs compared to North America and Europe, without compromising on quality.

-

Nearshoring proximity: Reduced shipping times and logistics complexity for U.S. and Canadian customers—shorter lead times and faster response to design changes.

-

Skilled workforce: Mexico’s aerospace clusters in Querétaro, Tijuana, and Chihuahua have cultivated a deep talent pool of engineers, machinists, and quality auditors trained to global aerospace standards.

-

Bilateral trade agreements: Mexico’s participation in USMCA (formerly NAFTA) facilitates tariff-free commerce with the United States and Canada.

-

Cultural alignment: Similar time zones and working hours foster real-time collaboration and project visibility.

What advantages do our facilities and capabilities offer?

Our Mexico-based factories feature:

-

30,000 ft² of climate-controlled production space equipped with laser cutting machines (fiber and CO₂), robotic press brake cells, and multi-head punch presses.

-

Dedicated finishing lines with anodizing baths, chromate conversion stations, and paint booths.

-

In-house machining centers for secondary operations, reducing outsourced dependencies and lead times.

-

Advanced metrology lab with 3D laser scanners, portable CMM arms, and automated inspection tables.

-

Dynamic material inventory stocking aluminum, titanium, stainless steel, and nickel alloys to accommodate urgent orders.

How do we ensure compliance with international aerospace regulations?

Our quality and compliance teams continuously monitor and implement:

-

Regulatory updates from FAA, EASA, and other authorities to maintain current approvals.

-

Supplier qualification programs to vet raw material vendors against aerospace material standards (AMS, ASTM, DIN).

-

Data security policies in line with ITAR, including access controls, encrypted document management, and employee training.

-

Environmental management through ISO 14001 practices—minimizing waste, recycling scrap, and responsibly disposing of hazardous materials.

What successful aerospace projects has our company completed?

Over the past decade, we’ve delivered:

-

Wing rib assemblies for a leading general-aviation OEM, achieving on-time delivery rates above 98% and reducing scrap rates by 35% through process optimization.

-

Satellite structural frames for a commercial launch provider, adhering to stringent mass limits (±1 g) and ensuring zero outgassing per NASA-STD-6016.

-

Landing-gear support brackets for a regional jet, meeting fatigue life requirements of 100,000 cycles under cyclic load testing.

-

Interior cabin panels for a major airline retrofit program, blending composite skins with aluminum stiffeners for weight savings and improved acoustics.

How can potential customers get a quote or contact us?

Engaging with our expert team is simple:

-

Submit your RFQ via our email ([email protected]), including CAD files and material specifications.

-

Receive a preliminary feasibility review within 48 hours, outlining material availability, lead times, and estimated costs.

-

Schedule a technical consultation with our engineering experts to refine design for manufacturability and finalize project requirements.

-

Approve the proposal to kick off production, with guaranteed tracking and milestone updates through our customer portal.

With unparalleled expertise in aerospace sheet metal fabrication, stringent quality systems, and the logistical benefits of nearshoring from Mexico, we stand ready to transform your designs into flight-worthy components. Whether you’re developing next-generation airliners, satellites, or high-performance drones, our turnkey solutions ensure you meet every aerodynamic, structural, and regulatory demand—on time and on budget.