Lifting the Industry on Thin Metal

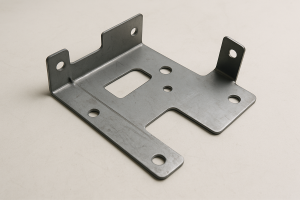

When most people imagine an aircraft assembly line, their minds jump to massive aluminum skins, carbon-fiber wings, or labyrinthine wire harnesses. Tucked behind every iconic airframe, however, is an ecosystem of thin-gauge sheet-metal parts—brackets, ribs, stiffeners, avionics trays, environmental-control plenums—that quietly keep everything aligned, cooled, and structurally sound. From private drones cruising at 400 ft to wide-body jets sprinting at 38,000 ft, aerospace programs still rely on sheet-metal fabrication to hit demanding targets for weight, strength, and cost.

This article explores how sheet-metal technology enables flight: the alloys that balance mass against fatigue life, the forming and joining methods tuned for aerospace tolerances, and the rigorous inspection regimes that keep hardware airworthy. Whether you are a design engineer laying out a satellite bus, a supply-chain leader qualifying a new tier-one vendor, or a start-up founder hunting for lighter eVTOL chassis, understanding aerospace sheet-metal fundamentals accelerates both innovation and certification.

Why Sheet Metal Thrives at Cruise Altitude

Weight-to-S trength Economics

Aerospace has a love-hate relationship with mass. Every kilogram shaved off a fuselage adds payload, range, or fuel margin. Thin-gauge aluminum or titanium sheet offers an unbeatable ratio of tensile strength to density. When formed into hat-section stiffeners or convoluted plenums, the shapes rival milled-from-solid parts at a fraction of the mass and raw-stock price.

Extreme Service Envelopes

Ice, salt fog, jet fuel, hydraulic fluid, 8-Hz vibration, –55 °C ground soak, and 120 °C bleed-air leaks—few environments punish metal like aerospace duty cycles. Sheet stock can be anodized, conversion-coated, passivated, or clad to survive decades of abuse. Its large surface-to-volume ratio also dissipates heat quickly, critical near flight computers and radar modules.

Reparability and MRO

Bolted doublers, bonded patches, or field-formable replacement panels allow maintainers to fix damage without pulling an entire subassembly. Sheet-metal parts can be removed with common shop tools, shipped flat as spares, and reinstalled with fresh fasteners—an advantage that composites still struggle to match outside of factory autoclaves.

Alloys in Orbit Around Flight

2024-T3: The Workhorse

With its high yield strength and moderate corrosion resistance (thanks to pure-aluminum Alclad layers), 2024-T3 remains the default for skins and stiffeners on legacy platforms. Its ductility supports tight bend radii in press-brake forming. Designers should note, however, that the copper content drives galvanic risk when fastened to carbon-fiber structures; isolating washers or sealant become mandatory.

7075-T6: Peak Strength, Finite Toughness

For highly-loaded fittings, actuator lugs, or missile fins, 7075-T6 delivers near-steel strength at half the weight. The trade-off is lower fracture toughness and poor SCC (stress-corrosion cracking) resistance. Many OEMs specify over-aged 7075-T73 for thick-section parts, sacrificing a bit of strength for a more forgiving fatigue margin.

5052-H34 and 5083-O: Weldability First

Auxiliary tanks, ECS ducting, and door surrounds often demand weldable grades. The magnesium-rich 5xxx series resists hot cracking during TIG or friction-stir welding and maintains excellent salt-fog corrosion behaviour. While ultimate tensile lags the 2xxx or 7xxx families, proper stiffener design closes the gap.

Ti-6Al-4V: When Heat and Weight Collide

Thrust reverser ducts, hot pylons, and hypersonic UAV control surfaces experience temperatures that rapidly over-age aluminum. Ti-6Al-4V retains strength above 400 °C and shrugs off galvanic coupling to CFRP, albeit at five-to-ten-times the material cost. Its springback behaviour during forming requires precise compensation in tool design and brake programming.

Cutting Metal for the Sky

Fiber-Laser Blank-and-Pierce

Modern fiber systems slice 0.4- to 6-mm aerospace alloys with kerf widths below 100 µm and positional repeatability under ±0.03 mm. Tight nesting algorithms push sheet utilization toward 90 %, critical for expensive titanium. Nitrogen assist gas prevents oxide scale, enabling weld-ready edges straight off the table.

Waterjet for Heat-Sensitive Laminates

Aluminum-bismuth stack-ups on space antennas or layered glare panels dislike the HAZ (heat-affected zone) of lasers. Fine-grit abrasive waterjets leave near-zero thermal input, albeit with slower feed rates and kerfs that must be deburred before chem-film.

Hard-Tool Nibbling for Million-Part Runs

Single-aisle aircraft program? Consider a turret punch with progressive hard tooling. Custom punch clusters can stamp 150 perforations per hit, producing speaker grill or flow-control plates at pennies per hole—once amortized across a decade of build cadence.

Forming Methods Tuned for Flight

Conventional Air-Bending on Servo Brakes

A six-axis back-gauge paired with high-resolution angle sensors enables ±0.2° accuracy across aluminum-lithium blanks longer than 2 m. Real-time angle correction heads off springback variability from batch-to-batch thickness drift. Shops log each hit into SPC dashboards to demonstrate process capability during AS9100 audits.

Draw Forming and Bulging for Complex Curves

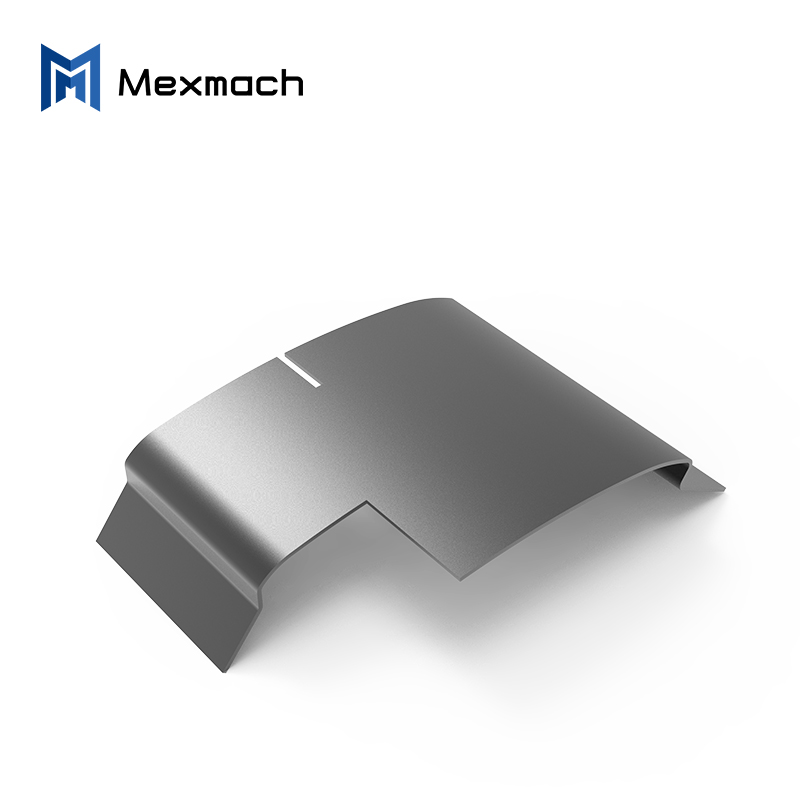

Cabin window frames and nacelle lip skins often require double curvature beyond a press-brake’s reach. Hydro-form bulging molds a blank over a die using 10,000-psi fluid, distributing strain evenly and avoiding localized thinning. For titanium, superplastic forming (SPF) at 900 °C stretches material 800 % without necking. Cycle times are long, but weight savings justify the autoclave hours on limited-run parts.

Incremental-Sheet Forming (ISF) for Rapid Dev

R&D teams iterating unmanned-air-taxi fuselage ribs lean on single-point ISF. A CNC orbiter tool incrementally depresses the sheet, one contour at a time, with no dedicated dies. Although surface finish is scalloped, parts emerge overnight at one-tenth the tooling cost of press dies—perfect for wind-tunnel models or flight-test spares.

Fastening and Joining Under Aerospace Scrutiny

Riveting: Still King of the Skin

Solid shank rivets (2117-T4) create fatigue-resistant shear joints when driven correctly. Automated ‘Flextrack’ riveting robots now squeeze 12 ppm across jumbo-jet panel lines, logging joint force waveforms for traceability. CherryMax blind rivets close up bays where only one-side access exists, such as wing box interiors.

Friction-Stir Lap Welds

Friction-stir welding (FSW) stirs aluminum in the plastic state, producing joints with parent-metal strength and zero filler contamination—ideal for cryogenic propellant tanks where porosity kills. Monitoring torque and plunge depth in real time flags tool wear before defects propagate.

Structural Adhesives and Co-Cured Bonds

Epoxy-film adhesives bond aluminum skins to CFRP spars, isolating galvanic couples and distributing loads across square feet rather than millimetres. Manufacturers scuff-sand and phosphoric-acid anodize faying surfaces to hit a peel strength above 200 N/25 mm, then co-cure at 175 °C to save autoclave cycles.

Laser Seam Welding for Battery Enclosures

Urban-air-mobility packs demand hermetic, lightweight cases. Continuous-wave fiber lasers weld 1-mm 5 xxx aluminum at 4 m/min, with penetration variation under ±0.05 mm. A coaxial vision system detects gap >50 µm and pauses the run for operator intervention, preventing leaks that would fail explosion-proof testing.

Finishing Treatments that Pass the Salt-Spray

| Finish | Purpose | Aerospace Typical Use | Thickness / Color |

|---|---|---|---|

| Sulfuric-Acid Anodize (Type II) | Corrosion + paint base | Exterior skins prior to primer | 5–18 µm, clear/black |

| Hard Anodize (Type III) | Wear, dielectric | Flap-track rollers, tooling | 25–50 µm, bronze/grey |

| Alodine 1200/600 (Type I chem-film) | Conductive corrosion coat | Avionics chassis ground path | <3 µm, gold/clear |

| Ti-CAD & Zn-Ni Plate | Sacrificial fastener protection | Steel Hi-Lok pins | 7–12 µm, dull silver |

| Powder Coat (AAMA 2604) | Cosmetic cabin panels | PSU housings | 60–80 µm, any color |

Every finish must survive 336 h salt-spray per ASTM B117 and still pass conductivity or paint-adhesion pull tests.

Inspection and Certification

First-Article Inspection (FAI)

AS9102 rev C demands ballooned drawings and traceable dimensions on the first production lot. High-volume suppliers use CMMs with 5-µm probes, while low-volume shops deploy portable 3-D scanners cross-checking GD&T profiles in minutes.

Process-Capability Indices

Cp/Cpk of ≥1.33 on key characteristics (bend angle, hole diameter) is the industry benchmark. Shops integrate brake-press sensors into SPC software feeding dashboards that trigger corrective action when Ppk drifts below 1.0.

Non-Destructive Evaluation (NDE)

Critical welds undergo fluorescent-penetrant inspection (FPI) or micro-focus X-ray. Rivet lines on pressurized fuselages are eddy-current scanned for surface cracks every C-check.

Digital Thread Compliance

The Digital Product Definition (DPD) standard mandates that the CAD model be the basis of inspection. Coordinate Measurement Machines import native CATIA or Creo data; any hand-edited DXF is grounds for corrective action during NADCAP audits.

Supply-Chain Challenges and Mitigations

Long Lead-Time Alloys

Aerospace-grade 7075 sheet with NADCAP heat-treat approval can run 20 weeks ex-mill. Smart buyers dual-source from stocking distributors and spot-order mill lots nine months out.

Counterfeit-Material Risk

Traceability down to the smelt batch and spectrochemical verification (OES or XRF) are non-negotiable. Suppliers embed barcodes tied to heat-lot certificates; receiving inspection cross-checks chemistry against the ERP record.

Rate-Ramp Bottlenecks

Commercial jet programs often double monthly build rate across 18 months. Laser cells with lights-out automation and modular fixture pallets allow sheet-metal suppliers to follow surge without weekend overtime.

Future Flight: Technologies on the Horizon

Hybrid Additive-Subtractive Cells

Directed-energy deposition prints stiffener ribs onto thin skins, then five-axis heads skim them to final thickness—eliminating rivets on fairings and saving 15 % weight.

Artificial-Intelligence Nesting

Cloud solvers crunch thousands of nesting permutations per minute, edging scrap rates below 5 %. For titanium at $35/kg, each percent is real money.

Digital Twins for Forming

Sensorized dies feed strain-maps to FEM software, tuning press-brake angles automatically after two trial bends instead of ten.

Smart Fasteners

Bluetooth-enabled torque-indicating rivets capture clamp load data and sync to the aircraft digital thread, easing maintenance records for airlines.

Conclusion

Sheet-metal fabrication might date to Wilbur and Orville’s bicycle shop, but it continues to evolve at Mach speed. The alloys are lighter, the lasers faster, the press brakes smarter, and the inspection now lives in the cloud. Yet the mission stays the same: transform flat stock into flight-worthy structures that survive vibration, corrosion, and every passenger’s demand for cheaper tickets.

MexMach stands ready to translate the latest aerospace sheet-metal science into hardware you can certify—whether you need five prototype ribs for a supersonic demonstrator or ten thousand avionics brackets for a next-gen satellite constellation. Reach out today to discover how MexMach pairs cutting-edge fabrication with on-time, AS9100-compliant delivery, ensuring your program soars from concept to orbit without turbulence.