For any manufacturer, choosing the right cutting method is a critical step in sheet metal fabrication. The process you select impacts precision, production speed, material compatibility, cost, and final product quality. With two of the most widely used technologies—laser cutting and waterjet cutting—it’s important to understand their differences before committing to one.

At first glance, both methods can produce precise, high-quality cuts. But they differ significantly in how they operate, what materials they can handle, and the costs and lead times associated with each. For procurement teams, engineers, and decision-makers, making the right choice can mean the difference between a smooth, cost-effective project and costly delays or rework.

This comprehensive guide will break down how each method works, where each excels, and how to choose the best option for your sheet metal projects—with insights from Mexmach, a leading sheet metal fabrication partner in Mexico.

What Is Laser Cutting?

Laser cutting is a thermal cutting process that has become a cornerstone of modern sheet metal fabrication due to its remarkable speed and precision. The technology utilizes a highly focused, high-power beam of light to cut materials.

How Laser Cutting Works

The term "laser" is an acronym for Light Amplification by Stimulated Emission of Radiation. In a laser cutting machine, a laser beam is generated in a resonator, amplified, and then directed through a series of mirrors to a cutting head. A lens in the cutting head focuses this intense light onto a single, tiny spot on the workpiece.

The concentrated thermal energy at this focal point melts, burns, or vaporizes the material. Simultaneously, a jet of assist gas, such as oxygen, nitrogen, or compressed air, is directed coaxially through the nozzle. This gas serves multiple purposes: it blows the molten material (slag) away from the cut, protects the lens, and, depending on the gas used, can aid the cutting process.

- Oxygen: Used for cutting mild steel. It creates an exothermic reaction that allows for much faster cutting speeds but leaves an oxidized edge.

- Nitrogen: Used for cutting stainless steel, aluminum, and other alloys. It acts as a shielding gas, preventing oxidation and resulting in a clean, high-quality, burr-free edge that is ready for welding without secondary processing.

The entire process is controlled by a Computer Numerical Control (CNC) system. Digital design files (like DXF or DWG) are translated into precise movement instructions for the cutting head, allowing for the creation of incredibly complex shapes and patterns with high repeatability.

Typical Materials and Thickness Ranges

Laser cutting is exceptionally effective for a wide range of metals. Common materials include:

- Carbon Steel (up to ~25 mm or 1 inch)

- Stainless Steel (up to ~20 mm or 0.75 inches)

- Aluminum Alloys (up to ~15 mm or 0.6 inches)

- Brass and Copper (requires specialized fiber lasers due to high reflectivity)

Advantages of Laser Cutting

- Exceptional Speed: For thin to medium-gauge sheet metal (up to about 12 mm or 0.5 inches), laser cutting is one of the fastest cutting processes available, making it ideal for high-volume production.

- High Precision and Accuracy: Laser cutters can achieve extremely tight tolerances, often within ±0.1 mm (±0.004 inches), and produce intricate geometries with sharp, clean corners.

- Excellent Edge Quality: When using nitrogen as an assist gas, laser cutting produces a smooth, clean edge that often requires no further finishing, reducing downstream labor costs.

- Low Kerf Width: The "kerf" is the width of the material removed during cutting. A laser beam has a very small focal spot, resulting in a narrow kerf. This allows for fine detail and tightly nested parts, maximizing material utilization and reducing scrap.

- Automation: The process is fully automated via CNC, ensuring high repeatability and allowing for "lights-out" operation, which can significantly reduce labor costs and increase throughput.

Limitations of Laser Cutting

- Thickness Limitations: While powerful lasers can cut thick plates, the process becomes significantly slower and less cost-effective compared to other methods as material thickness increases.

- Reflective Materials: Highly reflective materials like copper and certain brass alloys can be challenging to cut, as they can reflect the laser beam back into the machine, potentially damaging the optics. Modern fiber lasers have largely overcome this limitation, but it remains a consideration.

- Heat-Affected Zone (HAZ): As a thermal process, laser cutting introduces heat into the material adjacent to the cut line. This creates a small Heat-Affected Zone (HAZ) where the material's microstructure and mechanical properties can be altered. For most applications, this zone is negligible, but for certain sensitive alloys or applications requiring post-cut machining or welding, it can be a critical factor.

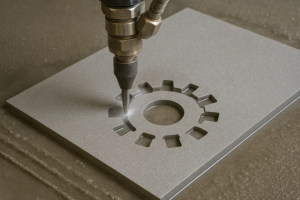

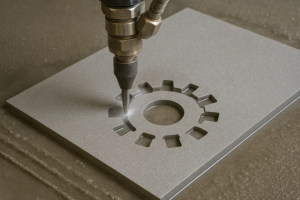

What Is Waterjet Cutting?

Waterjet cutting is a non-thermal, erosive cutting process that uses a jet of water at extremely high pressure to cut a vast range of materials. It is renowned for its versatility and ability to cut without imparting any heat stress to the workpiece.

How Waterjet Cutting Works

The principle behind waterjet cutting is accelerated erosion. A high-pressure pump, often generating pressures between 40,000 and 90,000 PSI (275 to 620 MPa), forces water through a tiny orifice made of ruby or diamond. This creates a fine, supersonic stream of water.

There are two main types of waterjet cutting:

- Pure Waterjet: Uses only the high-pressure water stream. This method is used for cutting soft materials like foam, rubber, gaskets, and food products.

- Abrasive Waterjet: For cutting hard materials like metal, stone, and composites, a granular abrasive (typically garnet) is mixed into the water stream in a mixing chamber after the orifice. The high-velocity water accelerates these abrasive particles, which perform the actual cutting action through micro-erosion. This is the method used for sheet metal.

Like laser cutters, waterjets are CNC-controlled, allowing them to follow complex digital paths with high accuracy.

Suitable Materials and Thicknesses

The single greatest advantage of waterjet cutting is its material versatility. It can cut virtually anything, including:

- All metals: Steel, stainless steel, aluminum, titanium, hardened tool steel, exotic alloys, copper, brass.

- Composites: Carbon fiber, fiberglass, laminates.

- Stone and Ceramics: Granite, marble, porcelain.

- Glass (except for some tempered glass).

- Plastics, rubber, and foam.

Waterjets excel at cutting thick materials. It's common for abrasive waterjets to cut metals over 150 mm (6 inches) thick, and they are capable of going much thicker, limited primarily by the time and cost one is willing to invest.

Advantages of Waterjet Cutting

- No Heat-Affected Zone (HAZ): As a cold cutting process, waterjet cutting imparts no heat into the material. This is its most significant advantage. The material properties are completely unchanged right up to the edge of the cut, which is critical for heat-sensitive alloys, aerospace components, and parts that will undergo extensive secondary machining.

- Cuts Virtually Any Material: From foam to titanium to granite, a waterjet's ability to cut nearly any material makes it an invaluable tool for prototyping, custom fabrication, and working with materials that cannot be cut by thermal methods.

- Exceptional Thickness Capability: Waterjets can cleanly and accurately cut materials far thicker than any laser can manage, making it the go-to choice for thick plate and block cutting.

- Excellent Edge Finish: A properly operated waterjet can produce a smooth, satin-like edge finish that is free of burrs and requires no secondary finishing.

Limitations of Waterjet Cutting

- Slower Cutting Speeds: Compared to laser cutting on thin sheet metal, waterjet cutting is significantly slower. The cutting head moves at a much lower feed rate, which translates to longer cycle times.

- Higher Operating Costs: The primary consumable in abrasive waterjet cutting is the garnet abrasive, which can be expensive. Additionally, the high-pressure pumps and components require regular, costly maintenance. These factors lead to a higher hourly operating cost than a laser cutter.

- Potential for Taper: On very thick materials, the waterjet stream can produce a slight V-shaped taper in the cut edge. Modern multi-axis CNC systems can compensate for this by tilting the head, but it is an inherent characteristic of the process.

Head-to-Head Comparison: Laser vs. Waterjet

| Feature |

Laser Cutting |

Waterjet Cutting |

| Primary Mechanism |

Thermal (Melting/Vaporizing) |

Mechanical (Erosion) |

| Heat-Affected Zone |

Small HAZ present |

No HAZ |

| Max. Thickness |

Good for thin-medium (~25mm) |

Excellent for thick materials (150mm+) |

| Speed |

Very fast on thin metal |

Slower, especially on thick material |

| Precision |

Excellent (±0.1 mm) |

Excellent (±0.1 mm), but speed dependent |

| Edge Quality |

Excellent, smooth, can be sharp |

Excellent, satin finish, no thermal stress |

| Material Versatility |

Good for most metals |

Cuts virtually any material |

| Kerf Width |

Very narrow |

Narrow, but wider than laser |

| Operating Cost |

Lower hourly cost |

Higher hourly cost (consumables, maintenance) |

Precision and Edge Quality

Both laser and waterjet cutting are celebrated for their precision. For most sheet metal applications up to 12 mm thick, both methods can hold tolerances that meet or exceed industry standards. The choice often comes down to the nature of the edge quality.

- Laser cutting produces an extremely clean, often shiny or mirror-like edge on stainless steel and aluminum when using a high-purity nitrogen assist gas. The edge is square and virtually burr-free. The only drawback is the micro-HAZ, which might affect subsequent high-precision welding or the fatigue life of certain critical components.

- Waterjet cutting delivers an edge with a uniform, sand-blasted (satin) finish. The key advantage is that this edge is completely free of thermal stress. This makes it the superior choice for materials where maintaining the original temper and structural integrity is paramount, such as in aerospace-grade aluminum, titanium, or hardened tool steels. For parts requiring a polished finish, the waterjet edge provides an excellent, stress-free surface for subsequent buffing and polishing operations.

Verdict: For general precision and a clean edge on standard metals, laser cutting is excellent. For heat-sensitive materials or when a perfect, stress-free edge is non-negotiable, waterjet is unbeatable.

Speed and Efficiency

This is where the two methods diverge most dramatically.

- Laser cutting is the undisputed champion of speed for thin to medium-gauge sheet metal. A fiber laser can cut through 1 mm stainless steel at rates of over 30 meters per minute. This incredible speed makes it highly efficient for mass production runs of brackets, enclosures, panels, and other typical sheet metal parts. The high speed directly translates to lower part costs and shorter lead times.

- Waterjet cutting is a much more deliberate process. The feed rates are considerably slower, especially as material thickness increases. While stacking thin sheets can sometimes improve throughput, it generally cannot compete with the raw speed of a laser on high-volume jobs for thin materials. The efficiency of a waterjet is not in its speed, but in its ability to perform tasks that other machines simply cannot, like cutting 4-inch thick titanium.

Verdict: For high-volume production of sheet metal parts under 12 mm (0.5 inches), laser cutting offers superior speed and efficiency. For prototypes, thick plates, or specialty materials, waterjet's slower speed is a necessary trade-off for its unique capabilities.

Material and Thickness Versatility

- Laser cutting is optimized for metals. It performs exceptionally well on carbon steel, stainless steel, and aluminum. While modern fiber lasers can handle reflective metals like brass and copper, there are still limitations. It is generally not used for non-metals like stone, glass, or most plastics (which can release toxic fumes when burned). Its practical thickness limit is around 25 mm (1 inch).

- Waterjet cutting is the definition of material-agnostic. If a material can be eroded, a waterjet can cut it. This opens up a world of possibilities for designers and engineers, allowing for the integration of metals, composites, plastics, and even natural stone in a single project, all cut with the same machine. Its ability to cut through metal plates over 150 mm (6 inches) thick places it in a class of its own for heavy-duty applications.

Verdict: If your project involves a wide variety of materials or requires cutting metal thicker than 25 mm, waterjet cutting is the clear and often only choice. If you work primarily with standard sheet metals in standard gauges, laser cutting is perfectly suited.

Cost Differences

The final cost of a cut part is a function of machine time, labor, and consumables.

- Laser cutting generally has a lower hourly operating cost. The main consumables are electricity and assist gases, which are less expensive than waterjet's primary consumable: abrasive garnet. Combined with its high speed on sheet metal, this results in a significantly lower cost-per-part for suitable applications.

- Waterjet cutting has a higher hourly cost due to the continuous consumption of abrasive garnet and the high cost of maintaining the ultra-high-pressure pump systems. The slower cutting speed also means more machine time per part. Therefore, for a simple steel bracket, a waterjet-cut part will almost always be more expensive than a laser-cut one.

However, the "cost-effective" choice depends entirely on the application. If a part requires a HAZ-free edge to avoid a high-cost failure down the line, the higher initial cost of waterjet cutting is a wise investment. Similarly, if you need to cut a 3-inch thick block of tool steel, waterjet isn't just cost-effective; it's the only viable option.

Verdict: For standard, high-volume sheet metal jobs, laser cutting is the more economical choice. For thick materials, specialty materials, or when a HAZ is unacceptable, waterjet provides value that justifies its higher cost.

Which Process Is Better for Your Application?

The best cutting method is the one that meets your project's specific requirements for quality, timeline, and budget. As your fabrication partner, Mexmach helps you navigate this decision. Here is a quick reference guide:

Choose Laser Cutting When:

- Speed is a priority: You have a high-volume production run with tight deadlines.

- Cost-effectiveness is key: You are working with standard sheet metals (steel, stainless, aluminum) in gauges up to ~12 mm (0.5 inches).

- High precision is required: Your parts feature intricate details, small holes, or sharp internal corners.

- A minimal HAZ is acceptable: The material is not overly heat-sensitive, and the edge will not undergo critical stress or precision post-machining.

- Typical Applications: Automotive brackets, electronic enclosures, decorative panels, machine guards, and general sheet metal fabrication.

Choose Waterjet Cutting When:

- A zero-HAZ edge is mandatory: The material is heat-sensitive (e.g., aerospace aluminum 6061-T6), hardened, or requires subsequent precision welding or machining without any change in material properties.

- You are cutting thick materials: The workpiece is a metal plate thicker than 25 mm (1 inch).

- The material is exotic or non-metallic: You need to cut titanium, composites, glass, stone, thick plastic, or highly reflective metals that are challenging for lasers.

- Stack cutting is an option: You have a large quantity of thin parts that can be stacked and cut simultaneously to improve efficiency.

- Typical Applications: Aerospace components, custom machine flanges, manufacturing of tools and dies, architectural elements from stone, and cutting laminated or composite materials.

How Mexmach Can Help You Choose the Right Process

Navigating the choice between laser and waterjet cutting requires expertise and a deep understanding of manufacturing realities. At Mexmach, we are more than just a service provider; we are your strategic manufacturing partner in Mexico.

Our team of experienced engineers and technicians has a profound understanding of how these cutting technologies perform on different materials and under various production scenarios. We work closely with our clients to analyze their project requirements, balancing the critical factors of cost, quality, material integrity, and lead times.

Whether your project is best suited for the high-speed efficiency of our state-of-the-art fiber laser cutters or the versatile, stress-free power of abrasive waterjet cutting, we have the technology and the expertise to deliver components that meet your exact specifications. We pride ourselves on providing not just parts, but solutions. We will guide you to the most effective and economical process, ensuring your project is a success from the very first cut.

Don't let uncertainty about cutting methods slow down your production. Partner with an expert who can deliver clarity and results.

Contact Mexmach today to consult with our specialists or to request a quote for your next sheet metal project. Let us put our expertise to work for you.