Types of Laser Cutting: A Comprehensive Guide

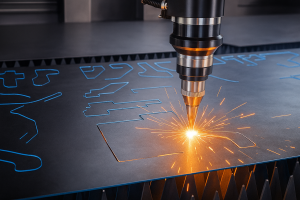

Release time:2025-08-05 Click:81Laser cutting is a powerful technology that uses a high-powered laser to cut materials into intricate shapes and designs. Its precision and ability to cut complex patterns make it a preferred choice in industries such as automotive, aerospace, electronics, and more. When it comes to precision manufacturing, particularly in sheet metal fabrication, laser cutting stands out as one of the most efficient and effective methods.

At MexMach, we specialize in precision sheet metal cutting services, and laser cutting is one of the core technologies we use. In this article, we will explore the various types of laser cutting, how they work, their advantages, and the applications for each type. By understanding the different types of laser cutting, manufacturers can select the right technique for their specific project needs and ensure high-quality, cost-effective production.

Laser cutting is a process that uses a focused laser beam to slice through materials, such as metals, plastics, and ceramics, with high precision. The laser generates concentrated heat at the cutting point, which melts, burns, or vaporizes the material. Laser cutting offers a high level of precision, speed, and quality, making it a preferred method in industries that require fine details, complex shapes, and minimal material waste.

The technology behind laser cutting has advanced significantly in recent years, enabling faster, more accurate, and cost-effective solutions for a wide range of applications.

There are several types of laser cutting technologies, each suited to different materials, thicknesses, and production requirements. Here are the most common types of laser cutting:

CO2 laser cutting is one of the most widely used forms of laser cutting, particularly for cutting thicker materials. It uses a carbon dioxide laser to produce a high-powered beam that is directed at the material being cut. The laser beam is generated by an electrical discharge passed through a mixture of carbon dioxide, nitrogen, and helium, creating a laser with a wavelength of approximately 10.6 micrometers.

In CO2 laser cutting, the laser beam is focused through a lens and directed at the workpiece. The heat from the laser melts, burns, or vaporizes the material. CO2 lasers are ideal for cutting metals like steel, aluminum, and stainless steel, and non-metals like wood and plastics.

Metal Cutting: CO2 lasers are used extensively for cutting sheet metal, especially in the automotive and aerospace industries.

Wood and Acrylic: CO2 lasers are also effective for cutting materials such as wood, acrylic, and rubber.

Signage and Design: CO2 lasers are commonly used for cutting intricate designs in a wide variety of materials, including plastics and metals, for applications in signage and decorative pieces.

High precision, ideal for intricate designs

Suitable for a wide range of materials

Capable of cutting thick materials efficiently

Fiber laser cutting is a newer, more efficient form of laser cutting that uses a solid-state laser instead of a gas laser like CO2. Fiber lasers use a fiber optic cable to generate the laser, which provides more power and higher energy efficiency than CO2 lasers.

Fiber lasers generate a laser beam by using an optical fiber doped with rare-earth elements, such as ytterbium. The beam is then transmitted through fiber optics to the cutting head, where it is focused onto the material. Fiber lasers are capable of cutting thin metals with high precision, and they are particularly effective for reflective metals such as aluminum, brass, and copper.

Metal Fabrication: Fiber lasers are ideal for cutting thin to medium metals such as stainless steel, aluminum, copper, and brass.

Electronics and Medical Devices: Due to their precision, fiber lasers are used for producing small, detailed parts for the electronics and medical industries.

Industrial Manufacturing: Fiber lasers are also employed in industrial applications that require cutting high-precision components for machinery, tools, and automotive parts.

High-speed cutting, especially for thin and medium materials

High precision and low heat input

Energy-efficient and cost-effective compared to CO2 lasers

The Nd:YAG (neodymium-doped yttrium aluminum garnet) laser is another popular type of solid-state laser used for laser cutting. Nd:YAG lasers produce a shorter wavelength than CO2 and fiber lasers, typically around 1.06 micrometers. This short wavelength enables Nd:YAG lasers to cut harder materials, such as ceramics, composites, and thick metals.

Nd:YAG lasers use a crystal that is doped with neodymium, which is optically pumped to emit a laser beam. This laser is focused onto the material and cuts through the material with high precision. Nd:YAG lasers are often used for spot welding and precision cutting of metals and are commonly used in industrial and medical applications.

Thick Metal Cutting: Nd:YAG lasers are ideal for cutting thick metals like steel and titanium in industries such as aerospace, defense, and heavy machinery.

Medical Device Manufacturing: Due to their precision, Nd:YAG lasers are used for cutting medical implants and surgical tools.

Jewelry Manufacturing: Nd:YAG lasers are often used in the jewelry industry for detailed engraving and cutting of precious metals.

High precision and excellent for fine cutting of hard materials

Ideal for cutting thick materials such as steel and titanium

Can be used for both cutting and welding applications

Disk lasers are similar to fiber lasers in that they use a solid-state laser, but they are based on a disk-shaped medium that provides a higher energy output. Disk lasers are ideal for high-power applications and can handle materials that require high-energy beams to cut.

Disk lasers use a disk-shaped laser medium, often made from ytterbium or other materials, to generate a laser beam. This technology offers better beam quality and can achieve higher power density than fiber lasers, making them ideal for heavy-duty cutting tasks.

Heavy Manufacturing: Disk lasers are used for cutting thick metals in industries such as automotive, aerospace, and shipbuilding.

Precision Cutting: Disk lasers are also used in precision applications that require high-quality cuts with minimal distortion.

Cutting of Non-Metal Materials: Disk lasers can also be used to cut non-metals such as plastics and composites.

Higher power output and energy efficiency

Ideal for heavy-duty applications

Produces excellent beam quality and cutting precision

Laser cutting offers many advantages that make it the ideal choice for sheet metal fabrication. The precision, versatility, and speed of laser cutting result in a range of benefits that can enhance manufacturing processes across industries.

Laser cutting allows for extremely high precision and accuracy, making it ideal for manufacturing intricate and complex designs. This is particularly important in industries like electronics, medical devices, and aerospace, where tight tolerances are critical.

Since laser cutting is highly focused, it minimizes material waste compared to traditional methods. The precise cuts reduce the need for additional processing, making laser cutting a cost-effective solution in the long run.

Laser cutting can be much faster than traditional cutting methods. The ability to cut quickly and accurately allows for high-speed production, which is essential in high-volume manufacturing environments.

Laser cutting is compatible with a wide variety of materials, including steel, aluminum, stainless steel, brass, plastics, and composites. This makes it a versatile solution for many industries, from automotive to electronics to medical.

Laser cutting produces less heat than traditional methods, which means the heat-affected zone is smaller. This results in minimal distortion and a cleaner final product.

Laser cutting is widely used in many industries due to its speed, precision, and versatility. Below are some common applications:

Laser cutting is used extensively in the automotive industry for creating body panels, brackets, and engine components. Its precision ensures that each component meets the stringent requirements of the automotive industry.

In aerospace manufacturing, laser cutting is used to create lightweight, durable components like structural parts, turbine blades, and wing brackets. The precision and strength of laser cuts are crucial in this highly demanding industry.

Laser cutting is ideal for manufacturing surgical instruments, medical implants, and device housings. Its precision and ability to handle small, intricate components make it essential in the medical field.

Laser cutting is used to produce enclosures, mounting brackets, and heat sinks for electronic devices. The ability to cut small, detailed parts with high accuracy is vital in electronics manufacturing.

At MexMach, we provide precision laser cutting services that meet the highest industry standards. Our team is equipped with state-of-the-art laser cutting technology, capable of handling a wide variety of materials and cutting requirements. Whether you need small prototype runs or large-scale production, we offer tailored solutions that deliver consistent, high-quality results.

Advanced Technology: We use the latest laser cutting machines to provide high-speed, high-precision cutting for various materials.

Expert Team: Our engineers and technicians have years of experience in laser cutting, ensuring that your projects are completed to the highest standards.

Cost-Effective Solutions: Our efficient laser cutting services help reduce production costs and minimize material waste, making us a cost-effective partner for your business.

Industries We Serve: We serve a wide range of industries, including automotive, aerospace, electronics, and medical devices, providing tailored solutions to meet the specific needs of each industry.

Contact MexMach today to learn more about our laser cutting services and how we can support your next project with precision, efficiency, and high-quality results.