What is Waterjet Cutting in Sheet Metal Fabrication?

Release time:2025-06-10 Click:142

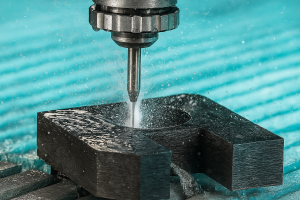

Waterjet cutting is a highly advanced and versatile method of cutting a wide range of materials, including sheet metal, using a high-pressure jet of water. Sometimes, an abrasive material is added to the water stream to enhance the cutting power, allowing it to slice through tough metals and other hard materials with remarkable precision.

The technology was first developed in the 1950s and has evolved into one of the most popular non-thermal cutting techniques for industrial applications. In sheet metal fabrication, waterjet cutting is especially valued for its ability to create clean, precise cuts without generating heat, thereby preserving the material’s original properties.

Waterjet cutting can be used to produce intricate shapes, tight tolerances, and smooth edges, making it an ideal choice for a variety of industries, from aerospace to architecture.

Waterjet cutting works by forcing water through a very small nozzle at extremely high pressures—often exceeding 60,000 psi (pounds per square inch). For most sheet metal applications, a mixture of water and an abrasive substance, such as garnet, is used to increase the cutting capability.

The process starts with a computer numerical control (CNC) system that guides the cutting head along a predetermined path, based on the design uploaded by the operator. As the high-pressure waterjet makes contact with the metal surface, it erodes the material along the cutting line, separating the sheet cleanly and efficiently.

Because there is no heat-affected zone (HAZ), the edges of the cut remain free from warping, discoloration, or microstructural changes. This cold-cutting process is one of the key reasons waterjet cutting is so valued in precision sheet metal work.

Waterjet cutting is favored in sheet metal fabrication due to its unique set of benefits. One of the main reasons is its ability to cut a wide range of metals, from thin foils to thick plates, without causing thermal distortion.

Other fabrication methods, like laser or plasma cutting, can introduce heat into the material, leading to changes in metallurgical properties or deformation. Waterjet cutting, on the other hand, preserves the integrity and strength of the base material.

Additionally, waterjet cutting produces extremely clean cuts with little to no need for secondary finishing, such as deburring. This can save time and cost in the overall manufacturing process. For industries requiring tight tolerances, detailed patterns, or delicate materials, waterjet cutting is an optimal solution.

Waterjet cutting is renowned for its versatility and can process virtually any sheet metal, including:

Stainless Steel: From thin sheets to thick plates, stainless steel is commonly cut for the food, medical, and aerospace industries.

Aluminum: Due to its softness and tendency to warp under heat, aluminum is ideally suited for waterjet cutting.

Mild Steel and Carbon Steel: Waterjet systems can slice through thick carbon steel plates without creating heat-affected zones.

Copper and Brass: Soft, conductive metals like copper and brass can be difficult for other methods but pose no problem for waterjet.

Titanium: Used extensively in aerospace, titanium’s high value means minimal waste and distortion is crucial.

Exotic Alloys: Nickel alloys, tool steels, and other specialized materials can be cut without altering their physical properties.

Waterjet cutting is also capable of processing layered materials, composites, and even some non-metals, but its primary use in sheet metal fabrication focuses on metals.

Precision is a key attribute of waterjet cutting. The technology is capable of producing cuts with tolerances as tight as ±0.1 mm (sometimes better, depending on the equipment and material). This level of accuracy is often comparable to or exceeds that of laser and plasma cutting, especially for thicker materials.

The lack of a heat-affected zone and the ability to follow intricate CNC paths means that even complex shapes and fine details can be achieved with remarkable repeatability. Waterjet cutting is regularly used for producing parts that require a high degree of accuracy, such as components for aerospace, medical devices, and electronics.

Waterjet cutting offers several distinct advantages, including:

No Heat-Affected Zone (HAZ): As a cold-cutting process, waterjet cutting preserves the mechanical and chemical properties of the metal.

Versatility: Suitable for virtually any type of metal, regardless of thickness or composition.

Precision and Repeatability: Capable of intricate cuts and tight tolerances, ideal for high-precision parts.

Minimal Material Waste: The narrow kerf (cut width) and efficient nesting of parts reduce scrap.

Clean Edge Quality: Produces smooth, burr-free edges that often require no secondary finishing.

Environmentally Friendly: Uses water and natural abrasives, creating minimal hazardous waste.

Ability to Cut Multi-layer Materials: Can process stacked sheets in a single pass, boosting productivity.

These advantages make waterjet cutting an essential tool in modern sheet metal fabrication.

Despite its many benefits, waterjet cutting is not without limitations. These include:

Cutting Speed: Waterjet is generally slower than laser or plasma when cutting thin sheets, though the gap closes with thicker materials.

Abrasive Cost and Management: Using abrasives increases operational costs and requires proper disposal.

Material Thickness: While waterjets can cut thick metals, the process slows as thickness increases. Very thick materials (over 6 inches) may not be practical for all machines.

Not Ideal for Every Application: For some tasks, other methods like stamping or punching may be faster and cheaper for high-volume runs.

Understanding these limitations is important when determining whether waterjet cutting is the best fit for a specific sheet metal project.

Waterjet cutting can be divided into two main categories:

This method uses only high-pressure water and is typically reserved for soft materials like plastics, rubber, and some textiles. It is less common in sheet metal fabrication due to the strength required to cut metals.

Most metal fabrication shops use abrasive waterjet cutting, where a fine abrasive (usually garnet) is introduced into the water stream. The mixture accelerates the cutting process, making it possible to slice through hard metals and thick plates.

Abrasive waterjet cutting is the preferred choice for the vast majority of sheet metal applications.

Each cutting technology has its own strengths and ideal applications:

Material Compatibility: Waterjet can cut virtually any metal; laser is better for thinner sheets and reflective metals may be challenging.

Thickness: Waterjet excels at thicker materials, while laser is faster for thin sheets.

Heat Effects: Waterjet produces no heat-affected zone; laser can cause melting or warping at the edges.

Edge Quality: Waterjet typically provides smoother edges, but laser can be faster and more cost-effective for thin, simple parts.

Precision: Waterjet is much more precise, with tighter tolerances and cleaner edges.

Material Thickness: Both can cut thick materials, but waterjet is less limited by conductivity or reflectivity.

Application: Plasma is ideal for fast, rough cuts on thick plate; waterjet is better for high-precision or multi-material jobs.

Choosing the right process depends on the project’s priorities: speed, cost, quality, material, and part complexity.

Waterjet cutting serves a wide range of industries, including:

Aerospace: Precision parts, minimal heat distortion, high-value metals.

Automotive: Prototyping, custom components, brackets, and chassis parts.

Architecture and Art: Decorative panels, signage, and intricate designs.

Medical Devices: Precise components, biocompatible metals, no heat effect.

Electronics: Small, delicate parts cut with high accuracy.

General Manufacturing: Machine parts, enclosures, supports, and more.

Each industry values waterjet cutting for its flexibility, quality, and ability to handle complex shapes without compromising material integrity.

Waterjet cutting is a go-to technology for prototyping and low-volume production. The reasons are clear:

Rapid Turnaround: No tooling or extensive setup is needed, so designs can move from CAD to finished part in hours.

Design Flexibility: Complex geometries, tight radii, and internal features are easily produced.

Cost-Effectiveness: For small runs or unique parts, waterjet avoids expensive molds or dies.

Material Conservation: Minimal waste is especially valuable when prototyping with costly alloys.

This makes waterjet cutting invaluable for R&D, startups, and custom fabrication shops where change and innovation are constant.

A typical waterjet cutting workflow for sheet metal includes the following steps:

Design and Programming: The part is designed using CAD software, then the design is translated into CNC code.

Material Preparation: The sheet metal is loaded onto the waterjet cutting table and securely clamped.

Setup: Nozzle and abrasive are selected based on material and thickness.

Cutting: The CNC-controlled cutting head follows the programmed path, slicing the material as directed.

Inspection: The cut parts are removed, cleaned, and checked for accuracy and quality.

Finishing: Any necessary secondary operations, such as deburring or surface treatments, are performed.

Efficient waterjet shops can process jobs quickly and accurately, from prototype to production runs.

The cost of waterjet cutting is influenced by several factors:

Material Type and Thickness: Harder and thicker materials take longer to cut, increasing time and abrasive usage.

Part Complexity: Intricate designs require slower cutting speeds and more machine time.

Quantity: Larger batches reduce per-part setup costs.

Finishing Requirements: If no post-processing is needed, costs can be lower.

Machine Rate: Hourly rates vary based on region, machine size, and shop experience.

On average, waterjet cutting is priced competitively with laser and plasma, especially for jobs requiring precision or heat-sensitive materials.

When selecting a waterjet cutting service, consider the following:

Experience: Look for providers with a track record in your industry and with your specific materials.

Equipment: Ensure they use modern, well-maintained CNC waterjets with capabilities matching your needs (thickness, part size, tolerances).

Lead Times: Choose a shop that can deliver on your schedule.

Quality Assurance: Ask about inspection processes and certifications (ISO, AS9100, etc.).

Customer Service: Clear communication and design support are crucial, especially for custom or prototype work.

Pricing: Request detailed quotes and compare value—not just cost.

By evaluating these criteria, you’ll find a partner who can deliver quality sheet metal parts on time and on budget.

The future of waterjet cutting is bright, driven by several trends:

Automation: Advanced CNC controls, robotics, and material handling systems are increasing productivity and reducing labor.

Eco-Friendly Practices: Innovations in water recycling and abrasive reuse are making the process greener.

Material Expansion: New abrasives and nozzles are enabling cutting of even harder and thicker materials.

Integration with Industry 4.0: Real-time monitoring, AI-driven optimization, and digital workflow integration are streamlining operations.

Customization: Growing demand for custom and short-run production favors flexible technologies like waterjet.

As manufacturing demands continue to evolve, waterjet cutting will remain a critical tool for high-precision, efficient, and sustainable sheet metal fabrication.

Waterjet cutting has transformed the sheet metal fabrication industry with its unique blend of versatility, precision, and material preservation. If your project demands clean cuts, tight tolerances, and the ability to work with a wide variety of metals—without the risk of heat damage—waterjet cutting is an ideal solution.

From aerospace to custom art installations, waterjet cutting meets the needs of modern manufacturing with efficiency and quality. Partnering with an experienced waterjet cutting provider can ensure your parts are delivered exactly as designed, ready for use or further assembly.

Interested in leveraging waterjet cutting for your next sheet metal fabrication project? Contact our experts for a free consultation and quote today!